In today’s digital age, data centres form the backbone of our interconnected world, ensuring the seamless operation of businesses, services, and technologies. The environments within these facilities are meticulously controlled, with every detail designed to protect critical infrastructure from risks. One such risk, often overlooked, is the presence of zinc whiskers – a phenomenon with the potential to cause significant damage to sensitive electronic equipment.

At EBD Steel Doors, we understand the unique demands of data centres, which is why we are actively involved in over 20 data centre projects, driving compliance and setting new standards for the UK and European market. To ensure safety and reliability, we have chosen not to use Zintec steel in our doors, eliminating the risk of zinc whisker formation. In this article, we explore what zinc whiskers are, their dangers, and how they can be prevented, while highlighting how our products are tailored to exceed the expectations of modern data centres.

What Are Zinc Whiskers?

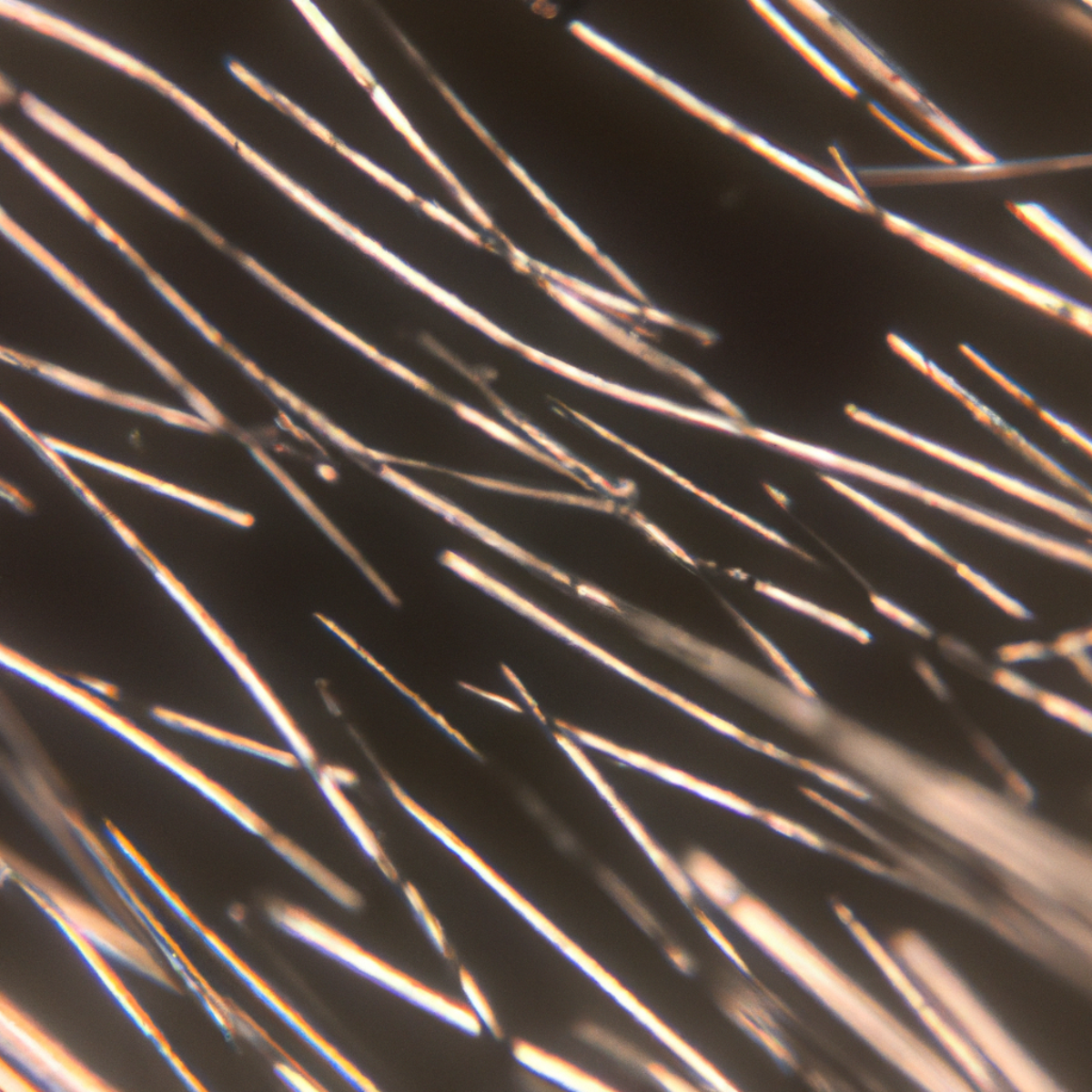

Zinc whiskers are microscopic, hair-like metallic filaments that form and grow on surfaces coated with electroplated zinc. Over time, mechanical stress, thermal fluctuations, or natural aging can cause these whiskers to detach from the surface and become airborne.

Although individual zinc whiskers are minuscule – typically just a few microns in diameter and up to a few millimetres long – their impact can be disproportionately large. Once airborne, they can infiltrate electronic systems, where their conductive nature poses a serious threat to operations.

Why Are Zinc Whiskers Dangerous in Data Centres?

Data centres house highly sensitive electronic equipment, operating under strict environmental controls to prevent malfunctions. Despite these precautions, zinc whiskers can bypass physical barriers and create severe issues, including:

- Electrical Short Circuits: Zinc whiskers, once airborne, can settle on circuit boards, bridging gaps between conductive components. This can result in electrical short circuits, potentially leading to catastrophic equipment failures.

- Operational Downtime: The fallout from zinc whisker-induced failures can include hours or even days of downtime while identifying and rectifying the issue. This can result in significant financial and reputational losses.

- Detection Challenges: Zinc whiskers are nearly invisible to the naked eye and require specialised equipment for detection. This makes them a hidden threat, often only discovered after damage has occurred.

As highlighted by the Centre for the Protection of National Infrastructure (CPNI):

“Zinc whiskers can cause electrical short circuits if they bridge closely spaced conductors, leading to costly outages in critical environments like data centres.”

How Can Zinc Whiskers Be Prevented?

The most effective way to mitigate the risks associated with zinc whiskers is through prevention, starting with the selection of materials. Here are the key steps we take to prevent zinc whisker formation:

1. Avoid Electroplated Zinc Coatings

Zintec steel, commonly used in various industries, features an electroplated zinc coating. While this material may be cost-effective, it is a known source of zinc whiskers. By avoiding Zintec steel entirely, EBD Steel Doors ensures that our products eliminate the risk of whisker formation.

2. Utilise Alternative Materials

Our doors are manufactured using high-grade steel without electroplated zinc coatings. This proactive approach eliminates the root cause of zinc whiskers, providing a safer alternative for data centres.

3. Implement Rigorous Quality Control

Preventing zinc whiskers also requires stringent quality control during manufacturing. At EBD Steel Doors, our processes adhere to the highest standards, ensuring that every product meets the specific needs of data centre environments.

4. Educate and Raise Awareness

Understanding the risks of zinc whiskers is crucial for stakeholders in the data centre industry. By sharing knowledge and insights, we help data centre operators make informed decisions about their infrastructure.

How EBD Steel Doors Surpasses Data Centre Expectations

Data centres demand more than just functionality; they require solutions that align with their standards for reliability, safety, and performance. At EBD Steel Doors, we go above and beyond to meet these requirements:

1. Material Expertise

Our decision to exclude Zintec steel is a testament to our commitment to providing fit-for-purpose products. We continuously evaluate industry trends and incorporate materials that enhance safety and longevity.

2. Bespoke Solutions

Every data centre is unique, and so are its requirements. Our doors are custom-designed to integrate seamlessly into data centre environments, offering features such as fire resistance and enhanced security.

3. Industry Collaboration

EBD Steel Doors are active with industry experts, architects, and data centre operators to stay ahead of emerging challenges. This collaborative approach ensures our products are always aligned with the latest advancements and standards.

As data centres continue to grow in scale and importance, the need for robust, reliable, and risk-free infrastructure has never been greater. With our active involvement in over 20 data centre projects, EBD Steel Doors combines industry expertise with a commitment to compliance, ensuring our solutions are tailored to meet the unique demands of these critical environments. By choosing EBD Steel Doors, you’re not just investing in high-quality products – you’re partnering with a company that truly understands your industry and works tirelessly to support its success.

For more information on our data centre solutions or to discuss your specific requirements, contact us here today.

You can read more on how Zinc whiskers affect your data centre here.